A crankshaft is used wherever there is a need to convert energy and power into rotary movements. A crankshaft uses connecting rods to transform the movements of the pistons into the rotational movements that drive the engine. Crankshafts are used in a wide variety of engines, from motorised chain saws and cars to diesel engines in ships.

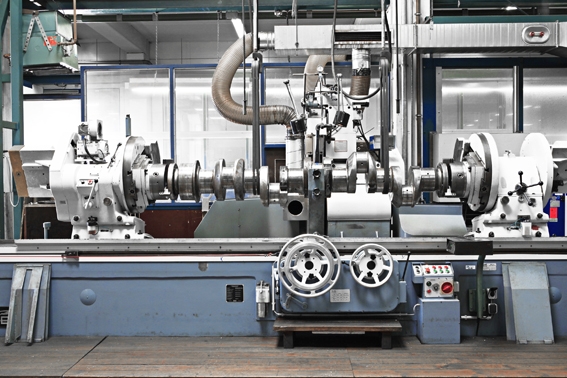

At Carl Baguhn we polish and grind crankshafts for four-stroke diesel engines with engine powers of approx. 50 kW or more (including the following makes: MAN, Wärtsilä, Vasa, Sulzer, Himsen, SWD, MWM, MaK, SKL, Crepelle and Volvo) and for compressors (including the following makes: Neumann & Esser, Maschinenbau Halberstadt, GHH, Mannesmann, Atlas Copco, Linde, Halberg, Maschinenfabrik Esslingen, Sabroe, Zwickau and Wurzner). We are also very familiar with special cases, e.g. crankshafts for canned food punch presses or steam engines. We machine steel, cast or laser weld build-up crankshafts for internal combustion engines, in-line engines and compressors on modern precision grinding lathes of various sizes.

As a specialist in grinding and polishing four-stroke crankshafts for marine and industrial applications, we regard the crankshaft as the heart of every engine. Accordingly we treat every crankshaft with the greatest care. Because inexpertly ground crankshafts can lead to premature bearing failure and considerable consequential damage, the many years of experience of our expert staff guarantee machining to the highest professional standards. Our precision and competence are reflected in the long lifetimes and reliability of the crankshafts that we machine.

As a company that grinds crankshafts for marine and industrial applications, it is advantageous that we have our business location in the immediate vicinity of the Port of Hamburg. This means we can serve our customers in the shortest possible time. In addition to crankshafts for marine and industrial applications, we also grind new (compressor) crankshafts to a specified crankpin journal diameter on a series production basis. In addition we also undertake grinding work not only on crankshafts but also on refrigerant compressor screws for example.

After more than 100 years of experience in grinding crankshafts, our company has access to an extensive and detailed data base with numerous four-stroke diesel engines and crankshaft types. Moreover, our experts can fabricate journal bearings for the respective crankpin diameters for diagnosis and machining purposes.

In conjunction with partner companies in the engine manufacturing and engine component repair industries, Carl Baguhn overhauls damaged main bearing journals and crankshaft bearing journals by laser weld build-up and mechanical machining. Crankshafts are annealed before alignment and regions of locally increased hardness on crankshaft pin and main bearing journals are reduced under the supervision of classification societies. We constantly re-comply with the highest quality demands and quality standards through close, trusting cooperation. Among other things this also holds true for the certification of our product or service provision areas in accordance with DIN ISO 9001:2008. At the same time, flexibility with regard to process scheduling is a matter of course for us.

Any use by us of any engine manufacturer’s brand or model name, product codes, part numbers or IMO numbers is for descriptive and/or reference purposes only.

Download our Workshop-Flyer:

GERMANY

Carl Baguhn GmbH & Co. KG

Wendenstraße 252-254

20537 Hamburg, Germany

PHONE

+49 40 251550

Fax: +49 40 25155150

Interested in working with us?

info@carlbaguhn.de