Precision, quality, reliability and on-time delivery: these are our commitments to the shipping and shipbuilding industries. Cylinder liners, pistons, cylinder heads, connecting rods and other components are all reconditioned to the manufacturer’s specifications – with satisfaction guaranteed.

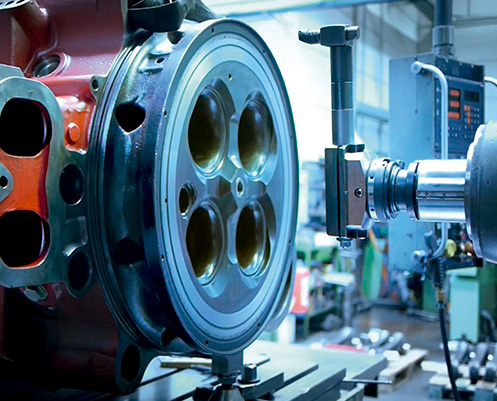

Honing is essential for proper functioning of a reconditioned marine engine. Before working on components, we clean them in our on-site wash facility and then prepare them for disassembly and diagnosis. Cylinder liners are checked for cracks around the flange and machined as required. In our Hamburg workshop, we use three different sizes of honing machine. After honing a component, its surface roughness values (Ra, Rz) and cross-hatch finish are restored to the manufacturer’s specifications. Finally, we create a set of measurement records.

In addition to our home base in Hamburg, Germany, we offer high-quality service through our global SCN members & partners.

Any use by us of any engine manufacturer’s brand or model name, product codes, part numbers or IMO numbers is for descriptive and/or reference purposes only.

Download our Workshop-Flyer: