Boring of tappet guides

If tappet guides become pitted or scored, the original diameter can be restored using the appropriate repair liners. To prepare the required bore, the Carl Baguhn tool is aligned using the stud bolts and a replacement camshaft. The block is then bored and the prepared repair liners, made from the same material as the block, are inserted and secured.

Skimming of cylinder liner seats

Carl Baguhn can also repair cylinder liner seats. Water and gas leaks can be easily remedied through in-situ grinding or skimming. For this operation, an engine-specific adapter plate is mounted on the stud bolts and the Carl Baguhn tool is aligned with the existing seat surfaces. The surface is then ground or skimmed depending on the depth of the leakage source. If the upper or lower seat is too heavily corroded, the crankcase can be re-bored to an oversize diameter and fitted with repair liners pre-treated with liquid nitrogen.

Honing of cylinder liners

Honing is an effective way of conserving resources and reducing operating costs. For this operation, a tubular rig is installed on the stud bolts to serve as a mounting structure for the pneumatic hoist and honing machine. A variable eight-arm honing head is then used to rectify the shape of the liner. Honing stones are available in a range of grain sizes and qualities (fine, rough and diamond) to cater for a wide range of liner materials and surface finishes. The honing liquid is collected in a container beneath the cylinder liner and pumped back up for reuse. The diameter and surface cross pattern of the two- or four-stroke liner are monitored throughout the honing process.

Measuring of cylinder liners on marine engines

Cylinder liner wear on the main engine can be measured and logged during a routine port call. The measuring instrument is installed through a scavenging port, so there is no need to remove the cylinder cover. Measurements of this type are increasingly requested by classification societies, insurance companies and lenders.

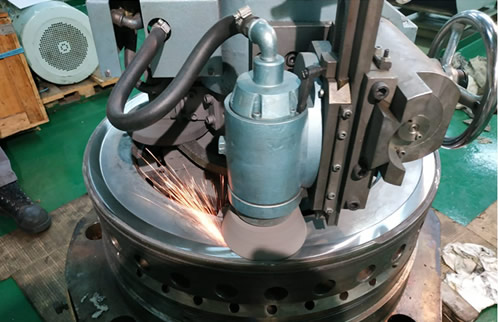

Skimming of crankshaft flanges

The crankshaft does not have to be removed in order to skim the crankshaft flanges. Our portable surface grinding machine is installed on the flange using an adapter plate and aligned with the aid of a dial indicator. The flange surface is then refinished using a diamond-coated disc.

Hardness testing (Brinell, Rockwell and Vickers)

Hardness is a measure of the resistance of solid matter to permanent deformation when a compressive force is applied. There are different methods for testing hardness based on the type of force applied. These methods are differentiated by the types of indenter used. The Brinell and Rockwell methods, for example, use a steel ball, while the Vickers test involves a pyramidal diamond. Our non-destructive hardness testing equipment can be carried as regular luggage to any location worldwide.